Monolithic systems lab creates synthesis, analysis and manufacturing tools for soft mechanical systems, compliant mechanisms and in general any device that deforms. Traditional machines with rigid links, joints and heavy actuators are designed using centuries-old knowledge often marked by a systems approach where kinematics, actuation and passive elements are decoupled. In contrast, bio-inspired soft mechanical systems have inherently coupled behavior, and extracting design methods pose a unique challenge.

We rely on design insight rather than purely computational techniques to tackle these challenges. Our hypothesis is that the design of physical systems such as soft and compliant mechanical systems can be insightful by the right representation of their physics. Our research makes fundamental advances in mechanics-based representation of soft and compliant mechanisms so that they are useful to design. We apply the design insight to several novel and practical applications in manipulation, wearable devices, locomotion and mechanical Metamaterials. Since our interest in design tools is domain specific, we are involved in the complete design cycle: conceptual design, embodiment design, prototyping, control, and testing. Our research can be broadly divided into (a) Mechanics-based modeling tools and (b) Application of these tools in products and other real world applications.

Please read on to understand past and current projects.

Mechanics-Based Modeling and Design Tools for Soft Robots

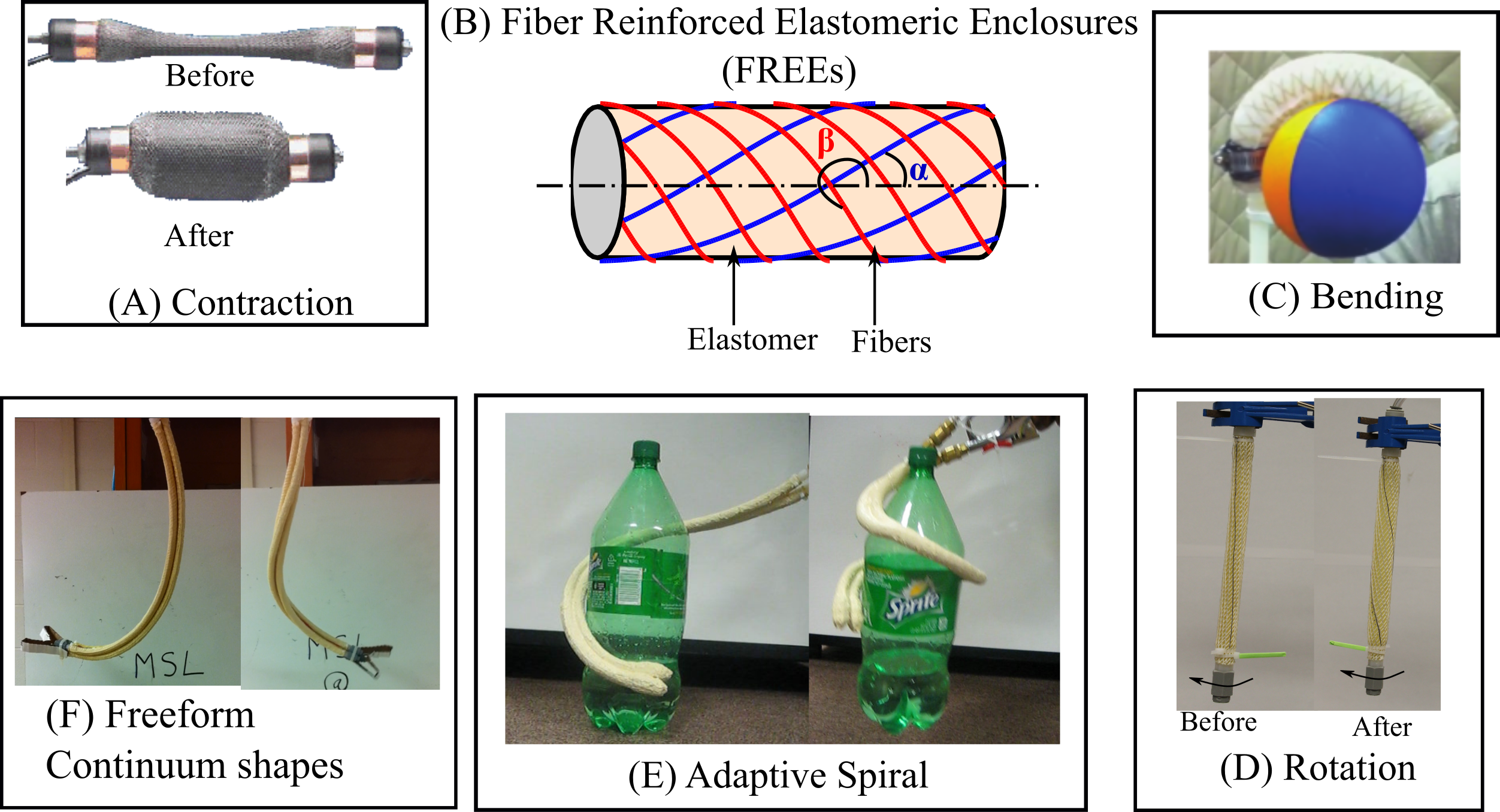

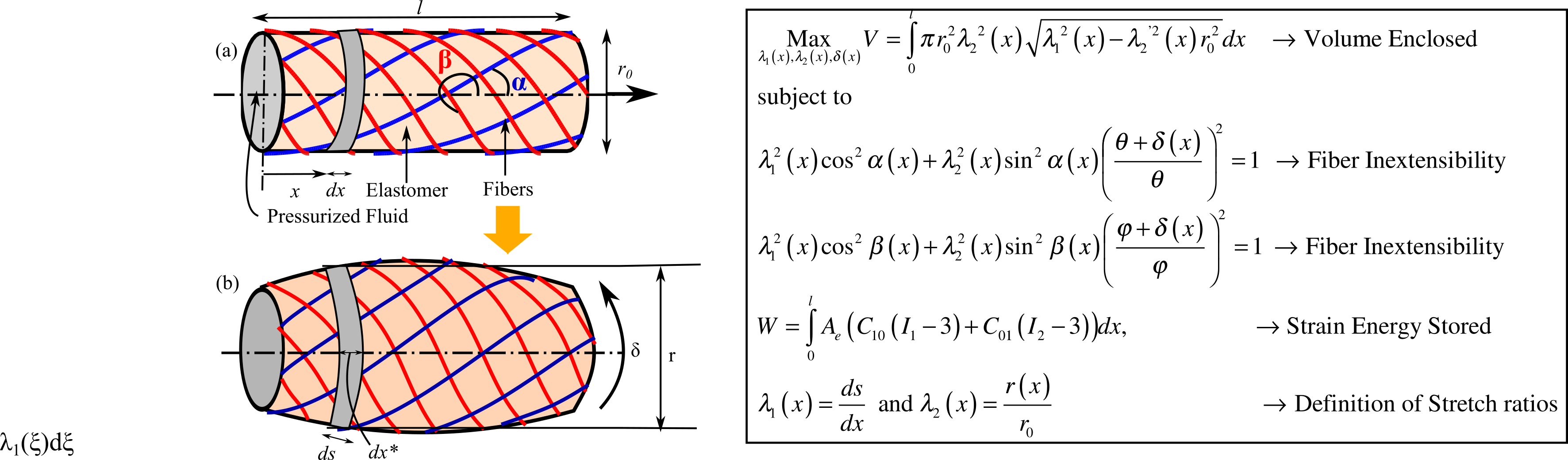

(1) Analysis and Synthesis of Fiber Reinforced Elastomeric Enclosures: We investigate the fundamental building blocks for soft mechanical systems known as the Fiber Reinforced Elastomeric Enclosure (FREEs). Fiber Reinforced Elastomeric Enclosures (FREEs) and are based in design and construction to the popular Pneumatic Artificial Muscles (PAM) or McKibben actuators. They constitute a hollow elastomeric core on which two families of helical fibers are reinforced. While in PAMs and their composite variants the two families of fibers are antisymmetric (see Figure below), FREEs permit arbitrary variation of fiber orientations. This not only broadens the design space, but also enables several spatial motion patterns that are otherwise unattainable with conventional actuators. To create knowledge on using FREEs for different applications, we require systematic modeling and analysis tools.

In this project, we are inspired by inflatables such as balloons and bellows that tend to maximize their enclosed volume subject to constraints imposed by seams. In FREEs these constraints can be due to the inextensibility of fibers.

Personnel: Gaurav Singh, Sreeshankar Satheeshbabu

Sponsors: NSF ERC for Compact and Efficient Fluid Power and NSF CMMI-1454276

Publications:

C14. Bishop-Moser, G. Krishnan*, S. Kota, ‘Force and Hydraulic Displacement Amplification of Fiber Reinforced Soft Actuators’, to appear in 2013 ASME-IDETC conference proceedings.

C13. Bishop-Moser, G. Krishnan*, C. Kim, S. Kota, ‘Design of Soft Robotic Actuators using Fluid-filled Fiber Reinforced Elastomeric Enclosures in Parallel Combination’, in-proceedings of the IEEE International Conference for Intelligent Robot and Systems (IROS), Vilamoura, Algarve (Portugal), October 7-12, 2012.

C12. Bishop-Moser, G. Krishnan*, C. Kim, S. Kota, ‘Kinematic Synthesis of Fiber Reinforced Soft Actuators in Parallel Combination’, presented at the 2012 ASME-IDETC/CIE, Chicago, IL, August 15-17, 2012.

C11. Krishnan*, J. Bishop-Moser, C. Kim, S. Kota. ‘Evaluating the Mobility Behavior of Fluid Filled Fiber Reinforced Elastomeric Enclosures’, presented at the 2012 ASME-IDETC/CIE, Chicago, IL, August 15-17, 2012.

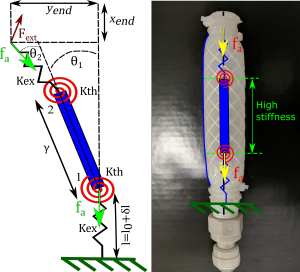

(2) Designing Systems of Fiber Reinforced Elastomeric Enclosures. Fiber Reinforced Elastomeric Enclosures (FREEs) are soft pneumatic representative elements that can form the basis for building soft self actuating structures/mechanisms. When placed in different configurations they exhibit unique stroke amplification characteristics that can be leveraged to create interesting deformation patterns. Such deformations occur as a combination of axial and bending deflection due to internal pressurization and external forces. This work presents a lumped reduced order model and a Homogenized Strain Induced Model that enables quick and accurate analysis of such mechanisms made from FREEs grouped as a system. The models serve as quick and accurate analysis tools for conceptual design of soft robots that occur as a combination of FREEs.

Personnel: Nicholas Thompson, Sreeshankar Satheeshbabu

Sponsors: NSF ERC for Compact and Efficient Fluid Power

Publications:

J19. S. Satheeshbabu and G. Krishnan, “ Modeling the Bending Behavior of Fiber Reinforced Pneumatic Actuators Using a Pseudo Rigid Body Model,” to appear in ASME Journal of Mechanisms and Robotics, 2019 (in press)

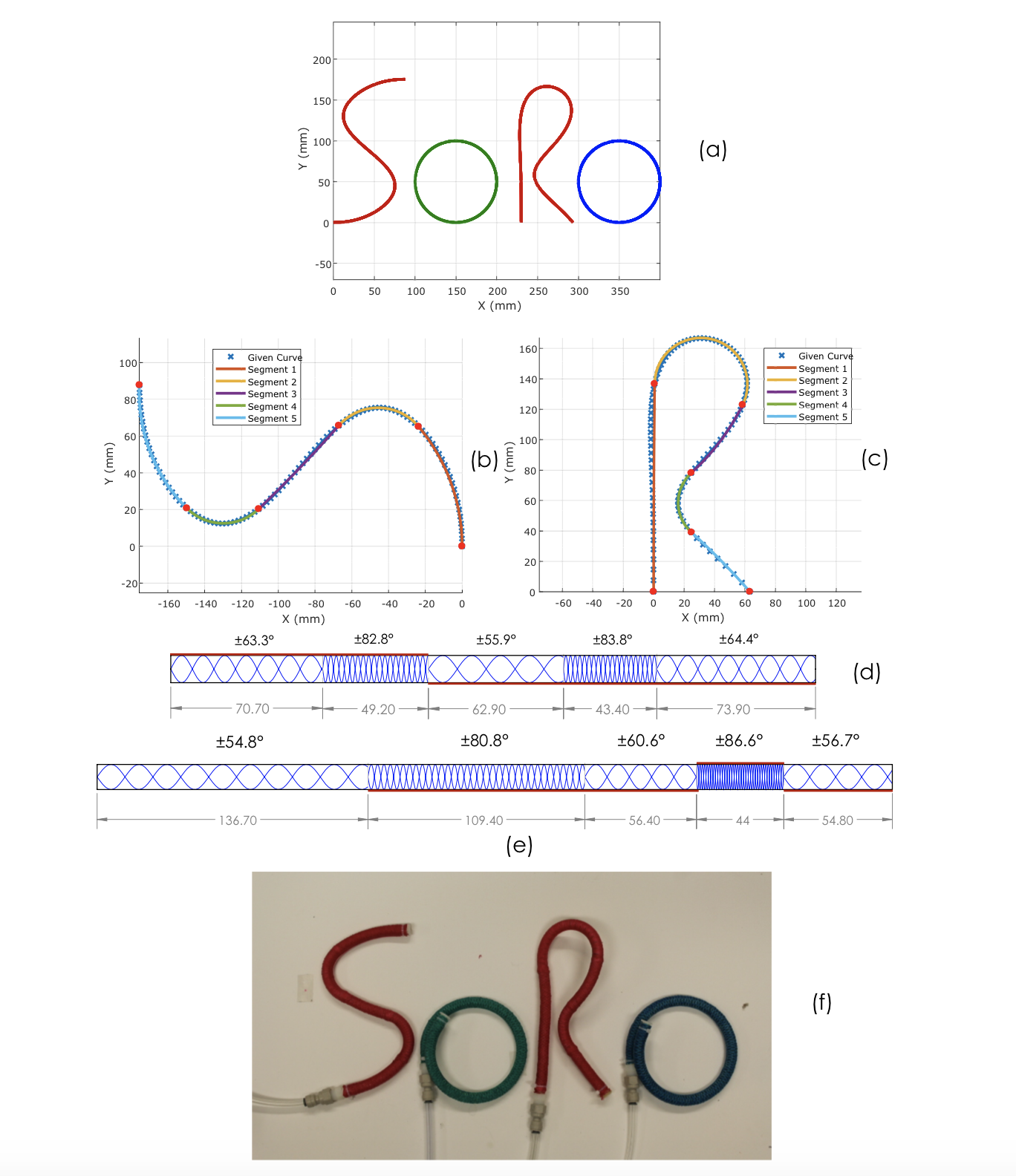

(3) Inverse Design of FREEs for large spatial deformation: There is a direct correlation between deformation of FREEs and their fiber orientations. This can be exploited to conduct an inverse design to optimize the FREE fibers so as to attain a required spatial deformation profile. We have studied this thoroughly for designing FREEs to match a planar curve and also investigated FREEs that undergo snake like spiral winding. Our results are presented as design maps or charts and can be used without the need for computationally intensive solvers. In the video below the FREEs are designed to take the shape of ‘SoRo’ the acronym for the soft robotics journal.

Personnel: Gaurav Singh, Naveen Uppalapati

Sponsors: NSF CMMI-1454276

Publications:

J20. Singh, G. and Krishnan, G., “Designing Fiber Reinforced Soft Actuators for Planar Curvilinear Shape Matching” submitted to the journal of Soft Robotics.

(4) Insightful Synthesis Tools for Spatial Compliant Mechanisms: Conceptual design of spatial compliant mechanisms with distinct input and output ports may be hard because of its complex interconnected topology, and is currently accomplished by computationally intensive automated techniques. Our work focuses on a user insightful method for generating conceptual compliant topology solutions. The method builds on recent advances where the compliant mechanism deformation is represented as load flow in its constituent members. The nature of load flow enables functional decomposition of compliant mechanisms into maximally decoupled building blocks namely a Transmitter member and a Constraint member. The proposed design methodology seeks to synthesize spatial compliant designs by systematically combining transmitter-constraint members by first, identifying kinematically feasible transmitter load paths between input(s) and output(s), and then selecting appropriate constraints that enforce the load path. We have built a Virtual Reality tool for users to follow simple guidelines and generate simple topologies.

Personnel: Sreekalyan Patiballa

Sponsors: NSF CMMI-1454276

Products and other Applications

(1) Design of Soft Pneumatic Crutch Orthoses (in collaboration with Prof. Elizabeth Hsiao-Wecksler, MechSE). This project has two main goals: to develop novel high-force, energy storing, miniature soft pneumatic actuators, and to directly integrate them as the structure for soft robotic upper extremity orthoses for pediatric patients that use crutches for ambulation. While walking with crutches, peak loads observed in the wrist typically approach 50% of body weight and wrist postures experience extreme extension angles ~35°. These repetitive, high loads and poor wrist postures have been shown to lead to joint pain and injury, carpal tunnel syndrome, arthritis, or joint deformity. Currently, the natural progression finds pediatric crutch users often transitioning to using wheelchairs, as their arms cannot support their body weight as they grow and the effects of these secondary injuries become unsustainable. This transition reduces mobility, fitness, and quality of life. Creating an effective orthosis would be beneficial for these pediatric patients or any assistive mobility device users, whom are susceptible to overuse injury and pain (those with acute limb injury or surgery, elderly, adult pathology populations).

We seek to develop a light-weight (< 1 kg), pliable (tunable modulus of rigidity), powered (by <100 psi) wrist orthosis and integrated compact actuators to reduce these transient loads and associated wrist stresses by 50% and improve wrist posture to a more neutral position; therefore lowering the risk for joint injury such as carpal tunnel syndrome, while allowing for normal wrist and arm range of motion when not used for load bearing. We will expand the range and functionality of current contracting McKibben muscles, which are based on simple equal and opposite fibers, by developing a robust analysis framework to generalize the construction and operating principles for FREE actuators to yield different deformation patterns.

Personnel: Gaurav Singh, Chenzhang Xiao

Sponsor: NSF ERC for Compact and Efficient Fluid Power

Publications:

P2. E. T. Hsiao-Wecksler, D. Farooq, C. Xiao, G. Krishnan, G. Singh, and Y. L. Oo, “Forearm and Wrist Support for Crutch Users,” US9662263 B2, 2017.

(2) Compact modular wearable upper-extremity exoskeleton: This project seeks to explore design architectures for wearable exoskeletons using miniaturized FREEs. It is well known that the forces in the pneumatic actuators decrease greatly when scaled down. However, to make exoskeletons wearable and discreet miniaturization is required. The only way to overcome this trade-off is by using multiple miniaturized FREEs in unique architectures. The architectures have different functionalities. A helical winding architecture just aids in stiffening the joint to assist in load bearing, while linear nested architectures produce large stroke to actuate. All the actuator architectures fit within the contours of the body.

Publications:

(2) BR2: A single section spatial manipulator. Soft pneumatic continuum manipulators are increasingly popular because of their ability to interact safely with humans, maneuver around obstacles and enable cost-effective operation. However, to increase their workspace, state-of-the-art soft manipulators are composed of independently controllable modular or serial segments that are complex to manufacture and integrate. Furthermore, they suffer from increased inertial effects and reduced load-bearing ability. We present the design and forward analysis of a first-of-its-kind purely parallel manipulator BR2, (one bending mode and two rotation modes) which is capable of spatial motion. This manipulator uses a repertoire of deformation patterns that are obtainable from novel pneumatic actuators known as Fiber Reinforced Elastomeric Enclosures (FREEs). Experimental characterization of the manipulator reveals the importance of a “coupling effect”, where the deformation mode of one actuator is restricted by the other. The inclusion of this effect along with gravity and other external forces is used predict the workspace of manipulator with reasonable accuracy.

Personnel: Naveen Kumar Uppalapati, Sreeshankar Satheeshbabu

Publications:

Uppalapati, N. K., & Krishnan, G. (2018). Design of soft continuum manipulators using parallel asymmetric combination of fiber reinforced elastomers. to be submitted to IEEE TRO.

(3) A pipe crawling robot: We present a pipe crawling robot gait using a three-FREE segment.

Past Research

(5) Design of Distributed Compliant Mechanisms using System-Level and Continuum-Level Design Maps : The objective of the project is to create a unifying framework for the synthesis of distributed compliant mechanisms by systematically channeling flow of information between the system-level and continuum-level phases in the design process. This flow of information is envisioned through two global design space maps that uniquely represent any compliant mechanism, namely (a) System Design Space (SDS) that characterizes the lumped system-level attributes, and a (b) Continuum Design Space (CDS) that characterizes topological, material and manufacturing attributes. The flow of information between the SDS and CDS will (i) enable objective comparison of several potential conceptual solutions based on inherent attributes that define the design space map, (ii) ascertain feasibility and existence of a solution by juxtaposing the problem specifications with these inherent attributes, (iii) enable synthesis of new designs at the system and continuum level by combining several sub-systems, (iv) set guidelines for systematic redesign of an existing solution to improve feasibility.

The theoretical underpinnings of the SDS and CDS will be enabled by three system and continuum level models namely, (a) Spring-Mass Lever model (SML) that characterizes the lumped behavior of any arbitrary compliant mechanism (b) a kinetostatic representation based on Load Flow Visualization that maps topological constituents of a compliant mechanism to its functionality and (c) a Distributed Compliance Metric that characterizes the state of stress distribution of the compliant mechanism.

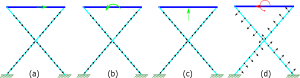

Personnel: Sreekalyan Patiballa and John Shanley

Mobility analysis of Flexure systems and Soft Mechanical Systems using Load Flow Visualization: Mobility analysis is an important step in the conceptual design of flexure systems. It involves identifying directions with unrestricted motion (freedoms) and those that are constrained. This paper proposes a unique framework for mobility analysis of wire flexures by characterizing a kinetostatic vector field known as “load flow” through its geometry. The relationship between load flow and the flexure axis is used to determine if a flexure behaves as a constraint or a freedom. This knowledge is utilized to formulate a matrix-based reduction technique to determine flexure mobility in an automated fashion. Several examples with varying complexity are illustrated to validate the efficacy of this technique. This technique is particularly useful in analyzing complex hybrid flexure topologies, which may be non-intuitive or involved with traditional methods. This is illustrated through the automated mobility analysis of a bio-inspired fiber reinforced elastomer pressurized with fluids. The proposed framework combines both visual insight and analytical rigor, and will complement existing analysis and synthesis techniques.

Personnel: Sreeshankar Satheeshbabu

Nonlinear Spring Synthesis for Orthotic Brace (with Adicep Inc): Recent research indicates that utilization of nonlinear mechanical energy storage devices (i.e. springs) can fundamentally change rehabilitative/assistive device architectures in ways that result in benefits not previously possible. Currently, no unified theory or design methodology exists that can help researchers in assistive devices create nonlinear springs. Moreover, commercially available nonlinear springs limit rather than enable their research. This proposal seeks to develop a design framework for creating distributed-compliance energy storage devices by researchers in assistive devices that addresses this problem. The proposed innovation is to incorporate the constant-stress hypothesis in synthesizing springs made of compliant members that undergo large deformation compared to their overall size. These synthesized springs must meet specified force/displacement functions satisfying fatigue and manufacturing requirements (e.g. weight, size, maximum stress).

Four tasks involving basic and applied research are planned. The basic tasks are (1) quantify and evaluate distributed compliance from the fundamentals of continuum mechanics and (2) create a design framework for synthesizing energy storage devices given user specifications; the applied tasks include (3) create a real-world nonlinear torsion spring for use in an orthosis and (4) develop a practical scheme for field adjusting the weight handling capability of the spring element in a lower-limb orthosis

Personnel: Sreekalyan Patiballa and John Shanley